-

Pre-communication

Pre-communication

-

Confirmation of products and nails

Confirmation of products and nails

-

Engineering evaluation

Engineering evaluation

-

Programme confirmation

Programme confirmation

-

Sign a contract

Sign a contract

-

Order production

Order production

-

Packing and Delivery

Packing and Delivery

-

Installation training

Installation training

Nail-pulling gun:

1. The nail-pulling gun should be handled lightly and not placed at will so as to avoid damaging important parts such as cylinders.

2. Installation, in accordance with the order of operation, the trachea, nail feeding pipe and induction line are inserted one by one to facilitate the normal use of the gun.

3. The nail-pulling gun must be replaced and maintained after a period of time for the long-term use of the gun.

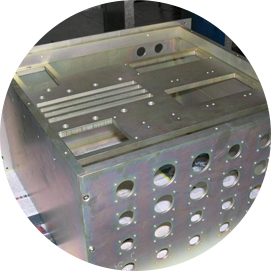

Machine:

1. Standard configuration: rated voltage: 220V/working pressure: 5-6kg/rated pressure: 2-3kg.

2. When working, make sure the working table is smooth.

3. When connecting the induction wire, the machine must be shut down. Be careful not to operate live.

4. When the machine runs, lock the foot brake, so as not to move easily and affect the production progress.

1. Clean the vibrating disc regularly to ensure that it is clean. It is suggested that when there is no rivet in the vibrating disc, the residue in the vibrating disc should be blown out with high-pressure air gun, and the vibrating disc surface should be cleaned with clean cloth once a day.

2. Clean the inside of the nozzle regularly, usually every day or every other day.

3. Refuel the nail-pulling gun regularly. It is recommended to refuel the nail-pulling gun once a day.

4. Fueling method 1: Take off the shell of the gun head, slowly loosen the fueling screw with the inner hexagonal wrench, let the excess oil or bubbles overflow, and check whether the combined gasket is damaged, if damaged, need to be replaced in time. Connect the gas source, let the filling hole align to the oil receiving barrel (remember not to align with personnel and other items), then press the trigger to remove the waste oil, stand upside down for a few minutes to let the waste oil drain clean. Use product configuration needle injector to fill hydraulic oil. Firstly, the injector is manually tightened to the filling hole to push the injector until it feels obvious resistance. Slowly loosen the injector push rod and repeat it several times until the oil product no longer bubbles. When the oil level is full, the injector is pushed out and the filling screw is locked. Install the head and shell of the gun, wipe off the excess oil spill, clean the gun and replace the oil.

The second refueling method is to remove the shell of the gun head, the vertical riveter, loosen the four fixed connecting screw and inverted riveter. After pulling out the cylinder, the piston disc is pulled out. Pour out the waste oil, loosen the filling screw with the inner hexagonal wrench, place it for a few minutes to let the waste oil drain clean, and check whether the combined gasket is damaged, if damaged, it needs to be replaced in time. Clean cylinder and piston disc, apply lubricating grease evenly on O-ring of piston disc and inner wall of cylinder with brush, push piston disc again and tighten bottom cover. Connect with the air source, after repeated empty pulling, the gun body is placed slowly to open the refueling screw, let the excess oil spill, then lock the refueling screw again, install the gun head shell, wipe off the excess oil spill, clean the gun, replace the oil product.

5. Clean the nail track regularly to ensure smooth operation of the nail in the track. It is recommended that the nail be cleaned twice a week.

6. Clean the nail feeding system regularly to ensure the smooth operation of the nail feeding system. It is recommended to clean the moving part with a high-pressure gun once a week and add a proper amount of grease.

7. Clean the outer surface of the chassis regularly.

8. Turn off the power supply every day after work or when not in use.

Respected Users:

Thank you for using Flying Efficiency products, we will wholeheartedly provide you with quality services.

Quality assurance

1. Within one week from the date of purchase, our company has inspected the product quality problem (the appearance of the product is not damaged), and we unconditionally replace the same type of products.

2. For products with warranty clauses, within one year from the date of purchase, when quality problems arise in normal use, the mainframe can enjoy free warranty service and implement lifelong maintenance service (only material labor cost is charged).

3. For products without warranty clauses, within one year from the date of purchase, the mainframe can enjoy free warranty service when quality problems arise in normal use, and implement lifelong maintenance service (only material labor cost is charged).

4. Accessories other than mainframe belong to vulnerable parts and are not covered by warranty. In order to ensure the quality of products, it can be guaranteed or replaced free of charge within one month (except for nail-pulling guns).