Product model: Dongli rivet gun

weight:1.35KG

Product unit: set

Pull nail specifications:

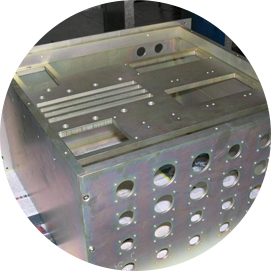

Application industry: chassis oven server wine box server

TEL:4006-784-785

| Dongli nail gun parameters | |||

| model | AR-700C2 | Intake pipe specification | 3/8" |

| Pullable stainless steel pull stud | 2.4mm | Air inlet specification | 1/4" NPT |

| Applicable rivet specifications | 2.4/3.2/4.0mm | net weight | 1.35kg |

| stroke | 14mm | full length | 232mm |

| pull | 2000 Ibs | Maximum tool tensionN(kgf) | 2400 |

| Operating pressure | 85-110PSI | Maximum stroke(mm) | 16 |

Check each part before assembly and replace (if necessary), thoroughly clean each part, remove the iron residue and apply dark green oil, do not forget to apply the air tube and the inner wall of the oil cylinder.

A good application is required to replace all prototype rings and exit rings, springs and stopcocks. This tool must be disassembled for any reason.

Untie the frame head, take out the air piston combination, fill the hole in the frame with 081 brand oil oil until the filling and the standard height of the liquid at the top of the circular ring are equal. Insert the air piston until the reverse of this solid The pressure is displayed on the combination air cylinder cover and locked with a wrench or a screw clamp.

Please specify that it is for 1/8"(3.2mm), 5/32 (4.0mm) and 3/16"(4.8mm) rivets, only a simple change of the nail device is required, without any other changes. Connect the tool train to the air supply, hold the trigger and press down to know that the nail tip device is loose, reinstall and re-lock; the nail head device can also be changed via the loose head frame.

1. Decompose the air supply by using the wrench to remove the skeleton head from these main parts.

2. The air cylinder flips the tool upside down and adjusts the cover of the cover. Pull out the air piston outwards and use the appropriate pliers to drain the power.(Warning: Be careful not to trap or scratch the air piston)Unscrew the skeleton nut lock by following the hole in the nail.

1. Unpack the air supply. Use a screw wrench to loosen the structure of the head and clean the inside of the head structure.

2. Hold the lock nut of the jaw box, unscrew the jaw box, and use the screw wrench from the oil plug to reopen the washer of the lock nut.

3. Release the jaw head from the jaw box and remove the jaw pusher spring, jaw pusher and a jaw.

Flying-effect automatic nailing machine is suitable for riveting and drawing of two or more layers of different materials and thickness through rivets.

Widely used in chassis, cabinet, lighting, automobiles, ships, airplanes, small appliances, servers, electric ovens, microwave ovens, liquor packaging and other industries to pull nails.